Many low-voltage professionals view NFPA 70 (National Electrical Code) as the domain of electricians. While the bulk of the requirements do apply to what we commonly refer to as “high voltage”, NFPA 70 is also applicable to the wiring of low-voltage systems.

Chapter 1 of the National Electrical Code covers common definitions used in the Code and general requirements for electrical installations. The definitions in Article 100 are important and form the basis of the code requirements. Therefore, it is important to read and understand the definitions in this chapter to understand the requirements that pertain to them.

Some important definitions include:

- Branch circuit – conductors between the final overcurrent device protecting the circuit and outlet(s) or equipment

- Cabinet – enclosure with a swinging door

- Overcurrent protective device – a device that interrupts the circuit when current exceeds a specified amount (i.e., circuit breaker or fuse)

- Raceway – enclosed channel for holding wires (i.e., conduit)

Chapter 2 of the National Electrical Code covers wiring and protection. Chapter 2 pertains to building electrical wiring requirements and applies to the primary power wiring going to a low-voltage system, as this wiring is typically the electrical contractor’s responsibility, not the low-voltage contractor’s.

Chapter 3 of the Code governs wiring methods for all circuits, including those with voltages of 1000 volts or less. This chapter generally applies to all electrical work, including low-voltage systems. Chapter 3 is a key chapter of the Code regarding wiring requirements. Properly installing electrical wiring is crucial for providing safe and effective electrical systems within the building. Here are some basic requirements that generally apply to allow low-voltage systems:

- Wiring installed under roof decking is required to be at least 1 ½ inches below the roof decking

- A junction box is required for each splice or termination point

- Penetrations in fire barriers are required to be properly sealed

- Wiring inside ducts is not permitted unless wiring applies to the direct functioning of the duct

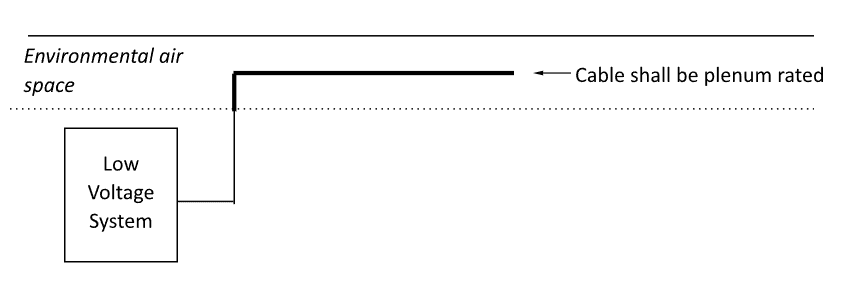

- Wiring or raceway installed in environmental air return spaces is required to be plenum-rated

- The installation of wiring cannot impede the removal of ceiling tiles

- The number of conductors permitted in an outlet box

- Approved bushings are required for conductors passing through a junction box knockout

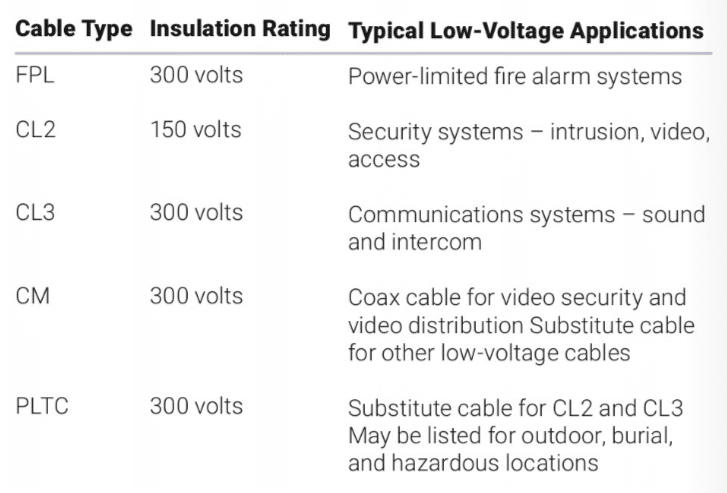

Low-Voltage System Cable Types

Low-voltage cables are categorized based on the circuit to which they are intended to be connected. Fire alarm systems require FPL-type cables, while other systems may use CL2-type or CL3-type cables. CL2 cables are commonly used in most security systems, including intrusion, video, and access control. CL3 cables are used on some sound and communications systems operating above the voltage limit for CL2 cables.

Modern, 24-volt fire alarm system circuits are power-limited systems that require FPL-type cables. Fire alarm circuit wiring is required to meet the wiring requirements in Article 760 of NFPA 70. FPL-type cables are typically 18 gauge or larger, but Article 760 permits them to be 26 gauge for multiconductor cable. FPL-type cables are required to have a jacket insulation rating of 300 volts.

Class 2 circuits are also power-limited circuits and require CL2-type cables. Class 2 circuits are covered by NFPA 70, Article 725, and are considered safe from a fire initiation standpoint, providing acceptable protection from electric shock. CL2-type cables have a jacket insulation rating of 150 volts.

Like Class 2 circuits, Class 3 circuits are power-limited circuits requiring CL3-type cables. Class 3 circuits are also covered by Article 725 and are considered safe from a fire initiation standpoint. However, they require additional safeguards against electric shock, as they may operate at higher voltage and current levels than Class 2 circuits. CL3-type cables have a jacket insulation rating of 300 volts.

Article 800 of NFPA 70 covers communications circuits and requirements for CM-type cables. Article 800 covers requirements for utility-provided telephone communications circuits that connect to customer equipment. Article 800 generally does not apply to security and fire alarm systems. Still, the CM-type cables identified in the Article may be substituted for CL-type and FPL-type cables. CM-type cables have a jacket insulation rating of 300 volts. Coaxial cable is commonly used in video security and distribution systems (antenna, satellite, cable). Coaxial cable is typically CM-type, making it suitable for most low-voltage applications.

A power-limited tray cable (PLTC) is covered by Article 725 and is a factory assembly of two or more insulated conductors rated at 300 volts, enclosed in a non-metallic jacket. PLTC-type cable is suitable for various applications and is commonly referred to as an “everything cable.” While PLTC-type cable is intended for use in cable trays, many PLTC-type cables are listed for use outdoors exposed (direct sunlight), direct burial (without conduit), and hazardous locations (presence of explosive materials). PLTC-type may be used as a substitute for CL2-type and CL3-type cables in general-purpose applications.

Cable Classifications

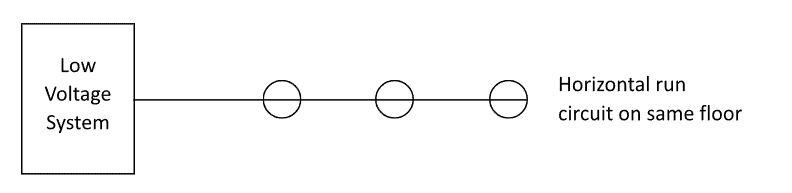

Cable used in low-voltage systems is classified by its intended application. A general-purpose cable is used for horizontal wiring from the control unit to devices on the same floor. A general-purpose cable may be used anywhere the cable is run on a single floor and does not run between floors or enter a plenum air space. General-purpose cable does not use a suffix to identify the application. For example, FPL, CL2, CL3, and CM are all general-purpose cables.

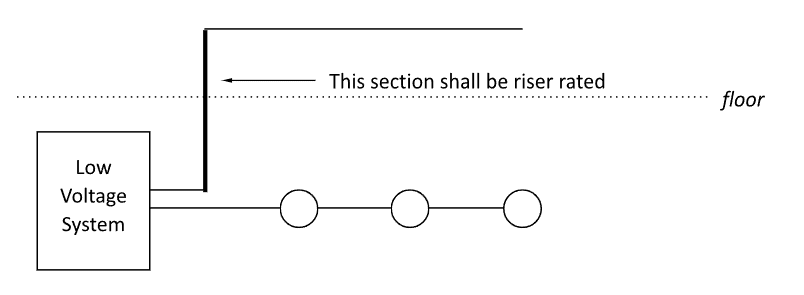

Riser cable is used for vertical runs between floors. The jacket on a riser cable is designed to resist the spread of fire along the cable when it is run vertically from floor to floor. Riser cable may be used in general-purpose applications, but general-purpose is not suitable for use in riser applications. Riser cable uses an “R” suffix on the cable designation to identify it. For example, FPLR, CL2R, CL3R, and CMR are all riser cables.

Plenum cable is used for cable runs in environmental air spaces (plenums). The jacket of plenum cable offers more fire resistance than general-purpose or riser cables and exhibits low-smoke-producing characteristics when burned. Therefore, plenum cables may be used in general-purpose and riser applications, but general-purpose and riser cables may not be used in plenum applications. Plenum cable uses a “P” suffix on the cable designation to identify it. For example, FPLP, CL2P, CL3P, and CMP are all plenum cables.

Learn more about low voltage systems in the NTC Blue Book, Low Voltage Systems Handbook. Training your team about the basics of low voltage systems in our New Employee Basic Training classes.